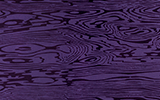

Urushi is a Japanese traditional natural lacquer. Unlike chemical lacquer, Urushi is the natural sap collected from the Urushi tree. It doesn't contain any hazardous substances or toxicity so it is friendly to the environment and to humans.

Exploiting this natural process, one scratches little by little the bark of the tree to obtain the Urushi sap during the period from June to November. Approximately 200g of sap can be collected during that period from a 14 to 15 year-old tree, enough to lacquer ten soup bowls. Once a certain quantity of sap is lost, the tree dies and is cut down in autumn. A new tree grows out of the stub of the old tree the following spring, renewing the process. The Urushi sap-scratching artisans have a saying "seven drops of Urushi is one drop of blood" so they take good care of the trees.

In English lacquer ware is called "japan" (like ceramic ware is called china), reflecting the history of Urushi lacquer ware in Europe as one of the most typical objects imported from Japan. Even today Urushi lacquer ware and lacquer crafts are one of the most representative traditional cultural objects of Japan.

How to collect Urushi sap lacquer

Exploiting this natural process, one scratches little by little the bark of the tree to obtain the Urushi sap during the period from June to November. Approximately 200g of sap can be collected during that period from a 14 to 15 year-old tree, enough to lacquer ten soup bowls. Once a certain quantity of sap is lost, the tree dies and is cut down in autumn. A new tree grows out of the stub of the old tree the following spring, renewing the process. The Urushi sap-scratching artisans have a saying "seven drops of Urushi is one drop of blood" so they take good care of the trees.

Characteristics of Urushi

Unlike paint which dries by evaporation, Urushi dries by a chemical reaction which provokes hardening by oxidation with moisture from the air and polymerization. The appropriate temperature (15 - 20 degrees C) and humidity (70 - 90%) are necessary to provoke this reaction. Under these conditions urushiol and laccase, components of Urushi, react chemically to generate a coating film. Once hardened it becomes a tough coating, very resistant to high heat and to the action of acid, alkali and alcohol. The drying process may require from a few to a dozen hours. If the correct conditions of temperature and humidity are not met, it may take more than one month to dry. That is why it is much easier to dry the Urushi lacquer in the humid rainy season than in the dry winter season. After each application the object is placed in a special drying cabinet which maintains a temperature and relative humidity appropriate for the proper hardening of the lacquer. This requires great experience and skill. Due to these conditions, the drying process is much more complicated than the painting process. It may also affect the quality of the coating, such as its color and brilliance. Normally, with paint, deterioration can be observed immediately after the painting is finished whereas Urushi's rich, smooth, beautiful coating will intensify in brilliance and color with time.Urushi in Japan

Initially Urushi was used as an adhesive for weapons and implements used in hunting. Later Urushi lacquer was developed as a coating for decorative objects, adding creativity and refinement to the advantages of its protective and resistant nature. It is said that the word URUSHI was derived from the words "URUWASHI - meaning beautiful" and "URUOSHI - meaning moisture" because of the shininess of its surface. The Chinese character representing the word "Urushi" contains symbols for water, tree and man, which explain well the characteristics of Urushi. Urushi's unique texture and brilliance match the Japanese people's sense of beauty which led them to develop Urushi lacquer ware. Through its long history Urushi lacquer ware has fascinated not only the Japanese people but also many people around the world.In English lacquer ware is called "japan" (like ceramic ware is called china), reflecting the history of Urushi lacquer ware in Europe as one of the most typical objects imported from Japan. Even today Urushi lacquer ware and lacquer crafts are one of the most representative traditional cultural objects of Japan.

Depending on the type of washi papers and places to use, the adjustments may be required such as; thickness of the adhesives, open time* and actual pasting processes. Please ensure to take a test papering.

*Open time : the time to penetrating the adhesive into the wallcoverings

*Open time : the time to penetrating the adhesive into the wallcoverings

- 1. Preparation and priming

-

- ・For the use of plywood and plasterboard wallboards, ensure that the wall surfaces are flat and smooth using the fillers. If the wall is in poor condition, apply the wallpapers primers. For mortared based wall, ensure it is plastered with dampproof agent to avoid discolouration over the paper-coverings cased by the humidity.

- ・Wallboads which don't absorb water are not recommended; such as resin plywood, anti-curve veneers, metal board. This is because Urushi agent is water resistant and is hard to exit water so wall-boards need to absorb moisture of the surface of wallcoverings to achieve the best finish.

- 2. Adhesives paste

-

- ・Please use non-formalin pastes for wallcoverings.

- ・This product is slightly harder in material than conventional wallcoverings therefore the adhesive pastes must be thick concentration and apply generous amount. (For further details, please follow the manufacturer’s instruction manual.)

- 3. Fixation

-

- ・This product is made by hand so please note that there maybe a slight difference in colours and patters for each sheet. Please align over a wall and adjust the overall balance prior to the actual fixation.

- ・Ensure that the patterns are matched side by side when joint the two sheets together. The repeat of the patterns is the width of the sheet.

- ・After applying the adhesive paste onto the sheet, allow enough time (10-15mins) to penetrate the glue into the sheet and adjust the time depending on the location, weather, temperature and humidity.

- ・Ensure to leave the sheet flat after applying the adhesive paste and do not fold the sheet to reduce the risk of leaving any folding marks over its delicate surface.

- ・When pasting over a wall surface, always pull and place gently with a brush removing any air bubbles between the wall surface and the wallcoverings. If it is difficult to remove bubbles, push them with plastic scrapers.

- ・For papering around the internal and external corners, ensure to trim and paste the sheet in exact size. Do not wrap the sheet, as bending sheet could damage the Urushi agent and cause the detachment.

※For use of furnitures and fusuma sliding doors,

Please use the plywood as a base. Follow the rest of the instructions as above.

- 4. Dealing with the joints

-

- ・We recommend to overlap the sheet. (margin of 10mm)

- ・For pasting the overlapped areas, mix the paste with synthetic plastic glue specially made for wallcoverings.

- ・Use sharp cutter for trimming and cutting, as the Urushi agent over the paper can be hard.

- ・After trimming, the similar coloured markers can be used to camouflage the trimming edge where necessary.

- 5. Other points to make

-

- ・This product uses Urushi lacquer agent which makes the same scent as the conventional lacquer objects. This is because of the urushiol agent. The scent would generally disappear within 1-3months.

- ・For people with sensitive skins, there maybe some allergic reactions. Please note that it will not be any harm once the main component of the urushi gets evaporated. However any problem occurred must be consulted by the specialist.

- ・Washi papers and Urushi can be discoloured by the ultraviolet rays. Protect from direct sunlight with curtains.

- ・Please note that this product is hand made and there maybe slight difference in colours and textures and patters compare to the samples provided. Please also note that all products are produced after taking orders therefore any additional orders may not come with the same result as the original lot orders.

- ・If you have any queries and questions concerning our product quality, please contact us before use of the product. Please note that we are unable to take any claims after cutting and fixing our products.

- 6. Maintenances

-

- ・Do not leave dirt and dust untreated for long time, as washi papers absorb humidity and grease that the dirt may stuck. Gently remove any dirt and dust with a duster or soft dry cloth.

- ・Remove any dirt and paste over the surface with a dump cloth and dry it with soft cloth. Do not rub the surface, as it could cause fluffiness.